Silicone render is increasingly recognized as a contemporary building material, distinguished by its exceptional durability and aesthetic qualities, making it a preferred choice for both residential and commercial projects in the UK and Ireland. This material comprises unique ingredients that enhance its performance, providing a range of benefits, including water resistance, flexibility, and breathable render characteristics. Various types of silicone render are available, each accompanied by specific application techniques, maintenance requirements, and installation methods that cater to diverse project timelines and customer preferences. It is also essential to consider the potential drawbacks associated with this material. Explore the reasons why silicone render may be the optimal choice for your upcoming project, considering its potential as a cost-effective solution with long-lasting protection and enhanced durability.

What Is A Silicone Render?

Silicone render represents a contemporary exterior wall cladding solution, recognized primarily for its waterproof protection and aesthetic appeal. It is engineered to offer not only a decorative finish but also enduring protection against a range of environmental factors, including UV radiation and moisture damage.

Notably, silicone render possesses hydrophobic properties that effectively repel water, rendering it particularly suitable for new constructions in humid climates where traditional renders may underperform. Additionally, its breathable render characteristics facilitate moisture control, thereby enhancing the durability of the façade surface, making it an ideal choice for new buildings.

How Is A Silicone Render Made?

The manufacturing process of silicone render entails the integration of advanced materials, including silicone resins and silicone silicates, which endow the product with distinctive properties such as flexibility, durability, and moisture resistance.

JUB silicone, a reputable brand in the industry, exemplifies high-quality formulations that ensure enduring performance across diverse climatic conditions.

The application process is carefully structured to address specific project requirements, guaranteeing optimal adhesion and a superior render finish on external walls, ensuring high standards of quality.

Uncover more: How To Do Silicone Rendering

What Are The Ingredients Of A Silicone Render?

The primary components of silicone render consist of elastic materials, silicone resins, and pigments, which collectively enhance its waterproof protection, cracking resistance, and render durability. The inclusion of acrylic render may also be implemented to improve workability and adhesion, thereby providing an effective balance between aesthetic appeal and functionality. These ingredients ensure that the silicone render retains its hydrophobic properties, making it an optimal choice for external wall applications.

The integration of various components significantly contributes to the overall efficacy of silicone render.

- Elastic materials play a critical role by allowing the render to flex and adapt to temperature fluctuations, thereby minimizing the risk of surface cracks often observed in traditional renders that lack this flexibility.

- Silicone resins are essential in achieving water-repellency and ensuring that the surface dries rapidly after rainfall, in contrast to conventional systems that can retain moisture, potentially leading to damage over time.

- Pigments not only provide color but also enhance UV resistance, ensuring vibrancy without fading, a common limitation of older render formulations.

- The incorporation of acrylic render grants additional adhesion properties, which is particularly advantageous for high-traffic areas.

This combination of ingredients distinguishes silicone render as a superior choice for durable and aesthetically pleasing exterior finishes, making it a viable alternative to traditional renders.

What Are The Benefits Of Using A Silicone Render?

The use of silicone render presents numerous advantages, establishing it as a preferred option for both homeowners and builders. Its remarkable durability provides long-lasting protection against environmental stressors, including moisture and UV rays, thereby contributing to the energy efficiency of buildings and reducing energy costs.

Additionally, silicone render is a cost-effective alternative when compared to other decorative protection systems and offers a variety of design possibilities, enabling an array of aesthetic finishes that accommodate diverse customer preferences.

Durable And Long-lasting

One of the primary advantages of silicone render is its exceptional durability and longevity, which are essential for external wall applications exposed to harsh weather conditions. This type of render withstands the test of time, requiring minimal maintenance and offering a cost-effective solution for homeowners seeking to enhance the aesthetic appeal of their property’s facade.

Silicone renders are specifically engineered with properties that enable them to resist moisture accumulation, cracking, and peeling—common issues that can affect less durable alternatives, ensuring render longevity. This resilience is achieved through a unique blend of polymers that impart flexibility, allowing the render to expand and contract without compromising its structural integrity. Additionally, its breathable nature facilitates the escape of trapped moisture, thereby preventing dampness and mold growth.

These attributes significantly contribute to the overall render longevity, making it an ideal choice for climates characterized by substantial temperature fluctuations.

- Moisture Resistance: Silicone render effectively repels water, which is critical in environments subjected to heavy rainfall.

- Crack Resistance: Its inherent flexibility reduces the likelihood of cracking resulting from structural movements.

- Low Maintenance: This product does not necessitate regular repainting or treatments, resulting in time and cost savings.

Homeowners who invest in silicone render can take comfort in the knowledge that their facade is well-protected, thereby minimizing the need for frequent repairs and enhancing the property’s visual appeal for years to come.

Water-resistant

Silicone render is widely recognized for its exceptional waterproof protection, rendering it an ideal option for buildings situated in damp climates susceptible to moisture damage and rain exposure. Its hydrophobic properties effectively prevent water infiltration, ensuring that the underlying materials remain dry and safeguarded against rot and decay.

The water-resistant characteristics of silicone render significantly enhance the maintenance and durability of structures over time. This innovative material functions as a barrier, considerably reducing the frequency of repairs typically associated with water damage, such as replacing decaying wood or addressing damp walls.

In terms of long-term investment, buildings treated with silicone render can experience several advantages:

- Extended Lifespan: By preventing moisture accumulation, silicone render contributes to the preservation of a building’s structural integrity.

- Lower Maintenance Costs: Its resistance to mold and mildew allows property owners to reduce cleaning and maintenance expenses.

- Enhanced Aesthetic Appeal: The smooth finish of silicone render not only provides protection but also enhances the property’s visual appeal, thereby contributing to its overall curb appeal.

In conclusion, silicone render represents a prudent choice for those seeking to bolster the resilience of their home or building against environmental elements, offering a combination of decorative protection, weather resistance, and flexible systems.

Breathable

A significant characteristic of silicone render is its breathable nature, which facilitates the escape of moisture trapped within porous materials, thereby preventing issues related to dampness and mold growth. This breathability is crucial for maintaining the structural integrity of buildings and contributes positively to indoor air quality while reducing potential environmental impact.

Understanding the importance of breathability in construction materials is essential for all professionals engaged in building design or renovation, as it impacts both structural integrity and indoor air quality. Breathable solutions, such as silicone render, provide a distinct advantage by ensuring effective moisture management. When walls are able to breathe, the risk of deterioration associated with trapped moisture is mitigated, fostering healthier living environments. This is particularly critical in regions characterized by high humidity levels, where condensation can result in significant structural damage.

Key benefits of utilizing silicone render include:

- Prevention of mold and mildew growth

- Enhancement of energy efficiency

- Improvement of occupant comfort

By opting for silicone renderings, both builders and homeowners can make a confident investment in a durable and efficient solution that not only protects their property but also offers aesthetic appeal.

Easy To Clean

One of the prominent advantages of silicone render is its self-cleaning properties, which significantly reduce maintenance requirements for homeowners, positioning it as an affordable option for home improvement. Its smooth surface finish and hydrophobic characteristics allow dirt and grime to be easily washed away by rain, helping to maintain a fresh and vibrant facade with minimal effort, thus enhancing the external wall’s appearance.

This exceptional capability not only decreases the need for frequent cleaning but also contributes to the material’s long-lasting integrity. As natural elements wash away pollutants and organic matter, the lifespan of the finish is extended, ensuring that the aesthetic appeal remains intact over years of exposure. Homeowners can notably anticipate less frequent repainting or heavy-duty cleaning, resulting in both time and financial savings.

- The hydrophobic surface repels water and prevents moisture accumulation, thereby reducing the risk of mold growth.

- Self-cleaning surfaces maintain their color and vibrancy, enhancing overall curb appeal.

- The use of silicone render can also improve energy efficiency by helping with temperature regulation.

Ultimately, adopting silicone render not only simplifies maintenance but also provides a durable and aesthetically pleasing facade that endures over time, making it a prudent investment for any property.

What Are The Different Types Of Silicone Render?

Silicone render is available in various types, including thin coat and thick coat silicone render, each providing distinct advantages suited for different applications and aesthetic preferences.

Thin coat silicone render is generally applied to achieve a smoother texture, while thick coat silicone render offers enhanced durability and is particularly suitable for uneven surfaces.

This demonstrates the versatility of silicone render as a solution for a wide range of project requirements.

Thin Coat Silicone Render

Thin coat silicone render is distinguished by its lightweight application, which facilitates a smooth and refined finish on facade surfaces. This type of render is frequently selected for its capability to create intricate design combinations while preserving a clean and modern aesthetic.

Plus enhancing the visual appeal of properties, this innovative material provides considerable advantages in terms of durability and weather resistance. In environments characterized by moisture and temperature fluctuations, the use of thin-coat silicone render proves particularly advantageous, as it adheres closely to surfaces without trapping moisture. Its inherent flexibility allows the render to expand and contract with the building structure, thereby minimizing the risk of cracking over time.

Applications of thin-coat silicone render include residential buildings, commercial properties, and public structures. It is especially suitable for use in coastal areas, regions prone to heavy rainfall, and urban environments.

By opting for this rendering solution, homeowners and builders can benefit from a resilient, low-maintenance facade that not only offers protection but also enhances the overall aesthetic of their structures.

Thick Coat Silicone Render

Thick coat silicone render is specifically engineered for robust applications, offering significant insulation benefits and enhanced durability. This makes it particularly suitable for external walls requiring additional protection against environmental elements. This type of render is frequently favored for its effectiveness in adhering to uneven surfaces, thereby ensuring a long-lasting finish.

This innovative material not only enhances the aesthetic appeal of buildings but also substantially contributes to their energy efficiency. By incorporating a thick coat of silicone render, property owners can realize the following advantages:

- Insulation Properties: The thick coat silicone render serves as an effective insulator, reducing heat loss during winter and minimizing heat gain in summer, thus maintaining comfortable indoor temperatures.

- Enhanced Durability: This render is resistant to moisture, mold, and environmental wear, ensuring the exterior of buildings remains protected over time.

- Versatility: Its adaptability allows for application in various environments, including coastal areas where salt and humidity can present challenges.

- Color Retention: With a wide range of color options, the render maintains its vibrancy and resists fading, thus enhancing the visual appeal of any property.

The remarkable benefits of thick-coat silicone render establish it as a preferred choice for homeowners and builders seeking long-term protection and efficiency.

How Is A Silicone Render Applied?

The application of silicone render entails a meticulous process that encompasses several essential steps to ensure optimal results and long-lasting durability.

Proper surface preparation is of utmost importance and may involve cleaning, priming, and repairing any damage to the external wall prior to the application of the silicone render.

Engaging skilled rendering contractors is often necessary to carry out these installation methods, as their expertise ensures adherence to project timelines and guarantees that the final outcome meets high-quality standards.

Preparation Of The Surface

Surface preparation constitutes a critical initial step in the application of silicone render, as it ensures both proper adhesion and the longevity of the finish. This process entails a thorough assessment of the condition of the building materials, meticulous cleaning of the surface to remove any contaminants, and executing necessary repairs to establish an optimal base for the silicone render.

Effective surface preparation is not merely a procedural formality; it plays a significant role in influencing the durability and aesthetic appeal of the render. A variety of techniques may be employed, including pressure washing to efficiently eliminate dirt and mildew, as well as sandblasting for deeper cleaning on textured surfaces.

The selection of materials is equally vital; the use of a premium primer can enhance adhesion while addressing moisture issues can preventing future complications. A well-prepared surface is fundamental to achieving a more robust and longer-lasting installation.

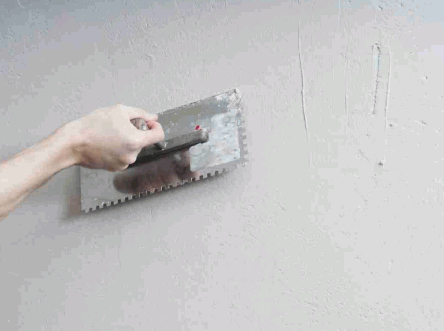

Mixing And Applying The Render

Once the surface has been adequately prepared, it is imperative to mix the silicone render in accordance with the manufacturer’s specifications to achieve the desired consistency and performance. Adhering to these guidelines ensures optimal durability and resilience, facilitating a homogeneous mixture that minimizes the risk of separation or inconsistency throughout the application process.

Following the required mixing ratios and techniques not only enhances the bonding properties of the render but also contributes to a long-lasting finish. This highlights the importance of employing professional application techniques. Improper application of the silicone render can lead to a variety of surface imperfections and compromise the overall integrity of the building.

- The selection of a trowel or sprayer can significantly influence the texture and finish of the application.

- Ensuring a uniform layer is crucial for achieving consistent color and preventing moisture accumulation.

- Each step in the application process must align with established quality standards to guarantee the best outcomes.

Ultimately, a meticulous approach to both mixing and application results in improved performance and aesthetic appeal, thereby reinforcing the investment in this essential aspect of construction.

Finishing Touches

The final step in the application of silicone render involves the addition of finishing touches to achieve the desired render finish and aesthetic appeal. This process may include texturing, smoothing, or applying additional layers to enhance the visual effect and ensure that the surface is adequately prepared to withstand environmental challenges.

These finishing techniques are essential, as they not only affect the render’s appearance but also its functionality. Several methods can be employed:

- Texturing: This technique imparts a handcrafted look, enhancing the depth and dimension of the surface.

- Smoothing: Attaining a flawless finish is crucial for both aesthetics and performance, as smoother surfaces are easier to clean and maintain.

- Layering: The application of additional layers can augment durability and improve the render’s resilience against harsh weather conditions.

When professionals meticulously consider these finishing touches, they ensure that the silicone render not only possesses visual appeal but also performs optimally over time, effectively protecting the underlying structure from moisture and other environmental stresses.

What Are The Maintenance Requirements For A Silicone Render?

Maintaining silicone render is a relatively simple process, owing to its self-cleaning properties and inherent durability. Conducting regular inspections and performing occasional cleaning are typically adequate measures to ensure that the render remains in optimal condition.

This proactive approach contributes to its longevity and sustained performance against environmental elements.

What Are The Potential Drawbacks Of A Silicone Render?

While silicone render, including options like JUB silicone and Premium Bio Silicone, offers numerous advantages, it is important to consider potential drawbacks, particularly concerning cost and installation methods. Typically, silicone render necessitates a higher initial investment compared to traditional or mineral renders, which may prompt some homeowners to reevaluate their options, especially when faced with budget constraints and cost considerations.

Furthermore, the requirement for professional application is crucial to achieving high-quality results, which can further elevate the overall expenses involved

More Expensive Than Other Renders And Insulation Systems

One significant drawback of silicone render is its higher cost compared to traditional rendering options or even some mineral renders, which may dissuade some homeowners from selecting this alternative. Although the initial investment may be greater, many experts contend that the long-term benefits, combined with features like thermal insulation, and decreased maintenance requirements, can justify the expense over time.

Considering the growing emphasis on sustainability and energy efficiency, the discussion regarding the cost of silicone renderings, particularly in regions like the UK and Ireland, has become increasingly pertinent. When evaluating the overall cost exchange, it is imperative to consider various factors, including installation, durability, external wall insulation benefits, and potential energy savings.

- Short-term costs: Traditional renders often entail lower upfront expenses, making them appealing to homeowners seeking budget-friendly renovation solutions.

- Long-term savings: Conversely, silicone render provides exceptional durability and resilience against moisture and mold, which can lead to substantial reductions in repair and maintenance costs.

Ultimately, the decision to invest in silicone render should take into account individual circumstances and preferences, weighing immediate budget considerations against projected lifetime savings.

Requires Professional Application

Silicone render, including ready-to-apply products like those from Weber and EWI Pro, typically necessitates professional application to attain the desired outcomes, which may pose a challenge for DIY enthusiasts. The requirement for skilled rendering contractors ensures that the installation methods are executed correctly; however, this may also contribute to the overall project costs and timelines.

While the attraction of silicone render lies in its modern finish and weather-resistant properties, homeowners must consider the extensive expertise required to manage the material effectively. The intricate nature of this process can lead to suboptimal results if undertaken without adequate training, resulting in issues such as improper adhesion or unsatisfactory aesthetic outcomes that may necessitate costly rectifications.

- Professional expertise not only ensures a superior finish but also minimizes long-term maintenance challenges.

- Experienced contractors are adept at navigating various factors, such as local climatic conditions and wall substrates, allowing them to tailor the application for maximum efficacy.

For those considering a DIY approach, it is essential to contemplate the potential challenges that may arise, which often lead to disappointment and unforeseen expenses.

Limited Color Options

Another consideration with silicone render is the relatively limited color options available compared to other decorative protection systems. While various pigment options exist, the selection may not meet the diverse preferences of all customers, particularly those seeking unique or custom colors for their projects.

This limitation can significantly impact design choices and aesthetic appeal, as clients often desire solutions that reflect their personal style or brand identity. When options are restricted, designers may be compelled to modify their vision or make compromises regarding the desired appearance, which could ultimately affect client satisfaction.

These restrictions, which can impact the client-designer relationship, may also lead to several challenges, including:

- An increased need for creativity in blending colors or utilizing patterns as alternatives.

- Additional costs and time are required to identify suitable alternatives or workarounds.

- Diminished project outcomes if the final result does not align with client expectations.

Ultimately, a limited color palette may strain the client-designer relationship, prompting a reassessment of the products available in the market.